Fiber Connector Types

What is a Fiber Connector?

The fiber connector is called a fiber optic or optical fiber connector. It is a precise coupling device that joins fiber optic cables quickly, enabling faster connection and disconnection than splicing. The connector mechanically orients the fiber cores, allowing light to pass and travel through the cable without interruption.

Unlike electrical connectors, fiber optic connectors allow light signals instead of electrical signals, which requires the connector to be much more precise. They have low insert loss, the best insertion repeatability, high return loss, and a long lifetime.

Although manufacturers have launched over 100 fiber connectors, only a few types are the industry’s most popular and widely used. Next, we will discuss the main types of fiber optic connectors.

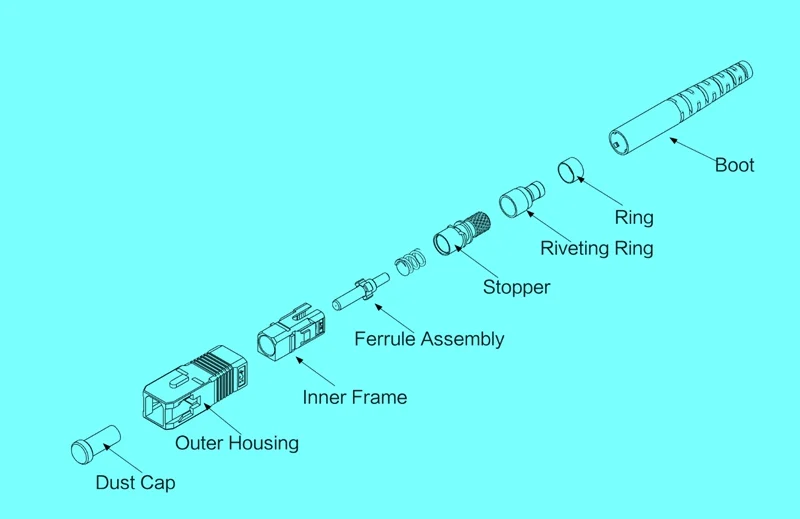

Structure of Fiber Connectors

Before going to the main section, let us explore the fiber connector structure. Although different fiber connectors have different structures, they generally share four essential parts: a ferrule, a connector, an attachment mechanism, and boots. The images below show the details of a typical SC connector.

SC Connector

The SC (Standard Connector, Subscriber Connector) is a fiber optic connector released by NTT in the mid-1980s. It is a snap-on square connector with a simple push-pull motion, similar to the push-pull latching mechanism of ordinary audio and video cables. It uses a 2.5mm diameter ferrule, twice the size of the later-developed LC connector.

Initially used in Gigabit Ethernet networks, the SC connector was adopted by the TIA-568-A specification in 1991. It has slowly gained popularity as manufacturing costs have decreased. Due to its outstanding performance, it has dominated the fiber optic field for decades. Still, In today’s fiber optic networks, SC connectors are among the two most common fiber optic connectors.

Due to the larger size of this connector, which requires more space for the same number of ports, it has slowly been replaced by more modern, streamlined connectors, such as LC and MPO connectors.

LC Connector

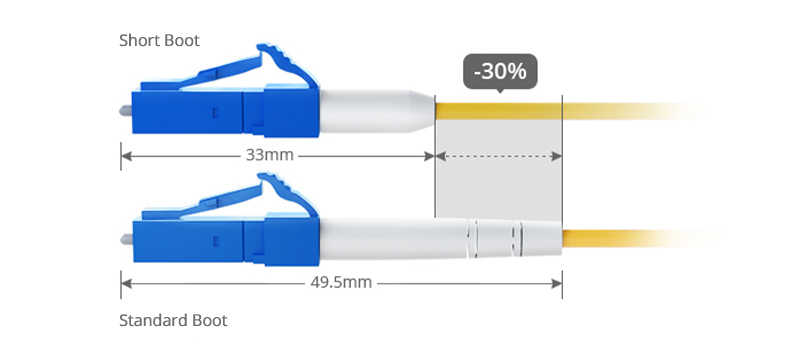

LC stands for “Lucent Connector.” Like its name, it was developed by Lucent Technologies. The LC connector has a 1.25mm ferrule, which is half the size of the SC. This small form-factor connector is extremely popular in datacoms and is perfect for high-density applications.

Nowadays, many people prefer high-efficiency cabling with LC fiber optic connectors. They are currently the most often used and successful ones.

Modern optical transceivers and active networking components feature LC connectors, expanding massive deployments and applications.

FC Connector

FC stands for “ferrule connector”. It is the first fiber optic connector to use a ceramic ferrule. However, unlike the plastic-bodied SC and LC, it uses a circular screw-type fitting made of nickel-plated or stainless steel. The end face of the FC fiber optic connector is inserted using an alignment key and then screwed into the adapter/jack using a fiber collet.

Despite the added complexity of manufacturing and installation, FC connectors still offer options for precision instruments such as OTDRs. In addition, FC’s screw-in collet is ideal for application scenarios in high-vibration environments because it ensures a solid fit with a spring-loaded collar.

It was initially designed for data center and telecom applications, but its use has declined since the advent of SC and LC fiber optic connectors. That is because it costs more, and the connection speed is slower than the SC and LC.

ST Connector

MPO Connector

MPO stands for Multi-fiber push-on connector. Unlike the conventional fiber connector, an MPO connector includes a fiber array that supports multiple fibers up to 12, 24, or 36 strands.

Due to their complexity, Multi-fiber connectors are not yet suitable for field-fit applications and must be factory-terminated. They are widely used in high-density data centers or fiber cabling systems that require space-saving.

Although the total cabling pricing is much higher than standard LC, SC, or FC connectors, the MPO fiber optic connector provides significantly fast deployment and inexpensive cost based on a ”per-fiber” basis.

MTP Connector

MTP® is a registered trademark of US Conec; it is an enhanced MPO connector, an abbreviation for Multi-fiber Termination Push-on. Compared with MPO, the MTP connector is an enhanced version of the Multi-fiber connector with improved accuracy, proven dependability, and better performance. Of course, its pricing is higher than the standard MPO.

MT-RJ Connector

MT-RJ stands for Mechanical Transfer Registered Jack. It is a duplex connector with female and male variants employing alignment pins. MT-RJ is almost no longer in use. Specific systems, however, may still require these connectors for maintenance. MT-RJ is only compatible with multimode duplex cables. Both fibers enter the ferrule, connected to its mated half via pins and holes, much like the MPO/MTP connector.

MU Connector

The MU (Miniature Unit Coupling) connector was developed by NTT, just like the Mini-SC. But unlike the SC, the MU connector has a 1.25mm zirconia ferrule. It uses a simple push-pull design, a compact miniature body, and a self-holding mechanism for backplane applications.

E2000 Connector

Diamond SA developed the E2000 connector. Also known as an LSH connector, it features a spring-loaded shutter mechanism to protect the ferrule end face from dust and laser beams. The E2000 fiber optic connector has a one-piece design for easy and quick termination and is suited for high-safety and power applications.

VSFF Connector

VSFF stands for Very Small Form Factor, a new term used to meet the increasing demands of hyper-scale and enterprise data centers.

According to CORNING, VSFF connectors are compact fiber optic connectors designed for small spaces. They are helpful in fiber network applications where space is limited.

SN, CS, and MDC are the most common types of VSFF connectors. In the following sections, we introduce those three types in detail.

These VSFF connectors are designed to meet the high demands of 200G/400G/800G data centers. The typical application scenarios include the VSFFC transceivers (such as QSFP-DD and OSFP), VSFFC fiber patch cables, and assemblies.

MDC Connector

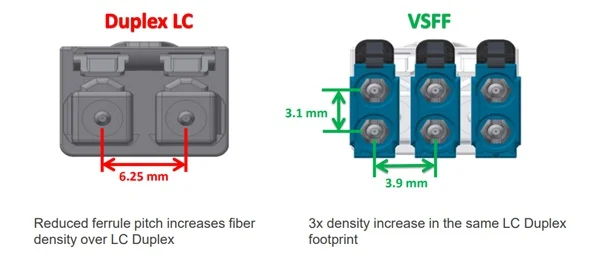

Short for the miniature duplex connector, the MDC connector was created by US Conec. It is a Push-Pull-Boot duplex fiber connector using industry-standard 1.25mm ferrule while providing three times the density of LC connectors.

As part of the Very Small Form Factor (VSFF) connectors portfolio, it targets SFP-DD, QSFP-DD, OSFP transceivers, and other high-density patching applications.

CS Connector

The CS connector is a new high-density, very small form factor (VSFF) fiber optic connector for QSFP-DD, OSFP, and COBO transceivers. Compared to an LC duplex, it delivers a 40% size reduction and doubles the density of patch panels.

SN Connector

The SN connector is a new duplex fiber optic connector developed by SENKO. It delivers higher density than the CS connector, using the industry-standard 1.25mm ferrule but reduced ferrule pitch; therefore, it offers a 4x duplex fiber connector with the same LC size. It is ideal for next-generation hyper-scale data centers, Edge, Enterprise, or co-location DCI.

ESCON Connector

IBM developed Enterprise Systems Connection (ESCON) in the early 1990s as a serial half-duplex optical fiber interface to improve connectivity by incorporating fiber optics into a network. The ESCON fiber optic connector uses 2.5mm ferrules to mate with SC or ST connectors via fiber adapters. However, to this day, ESCON is being displaced by the industry’s newer and more efficient SC and LC connectors.

FDDI Connector

FDDI is an abbreviation for Fiber Distributed Data Interface, which refers to a local area network technology such as Ethernet or Token Ring. Like the ESCON connector, the FDDI connector, also known as a MIC (Media Interface Connector) connector, is the termination on the fiber optic cable itself. It has two ferrules in a huge, heavy plastic housing with a squeeze-tab retention mechanism.

SMA Connector

SMA is the acronym for “Subminiature A,” Amphenol created in the late 1970s. The ferrule of the model SMA was precisely 1/8 inch in diameter and mated in a machined adaptor. When the adapters were not accurate enough for superior fiber performance, a necked-down ferrule coupled with a Delrin adapter was used.

Because of its key drawbacks, the SMA fiber connector is a commonly used multimode fiber with a very tiny market share. It is used only in minimal medical, materials processing, spectroscopy, sensing, and quality inspection applications.

Q-RMC Connector

The Q-RMC, or Rosenberger Multifiber Connector, is a durable industrial connector that uses the multi-fiber MT ferrule from the MTP®/MPO connector. It can accommodate up to 24 fiber cores. The connector features a push-pull closing mechanism, making connecting even in tight spaces easier and quicker.

With IP67 protection, it is waterproof, dustproof, and corrosion-resistant. It is suitable for use in extreme temperature environments (-40~80℃). Because of these qualities, it is ideal for industrial, mining, mobile communication (FTTA), 5G Base Stations, broadcast, and intelligent grid cabling applications.

How To Choosing a Fiber Connector?

Still, trying to figure out how to choose the correct fiber optic connector? Check the following helpful steps.

Step 1: Know the fiber count and connector type

Choose the connector type based on your existing equipment and long-term plans. Select the LC connector if you are using the most common SFP module. If you use a QSFP28 module, you may choose an MPO or LC connector. SC and LC are the most common choices. MPO is for high-throughput data centers, and VSSF connectors such as CS and SN are for 400G and beyond fiber cabling applications.

Step 2: Know the fiber type

Like fiber cables, they can be commonly categorized into single-mode and multimode fiber connectors.

Single mode fiber connector permits one light mode to propagate simultaneously, offering the longest transmission distance.

The multimode connector allows many light modes to propagate through the fiber, supporting a very short distance but lowering cabling costs.

Those fiber connectors usually have different color codes for easy identification. Single-mode connectors typically have blue or green covers, while OM1/OM2 multimode connectors have beige covers, OM3 has aqua, and OM4 has magenta.

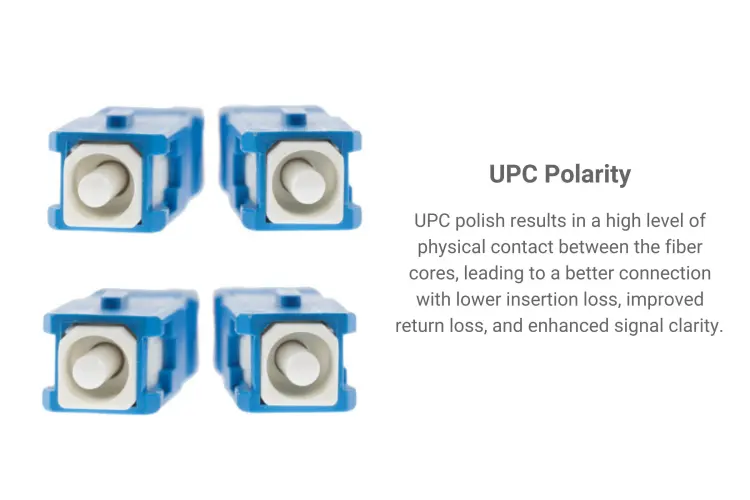

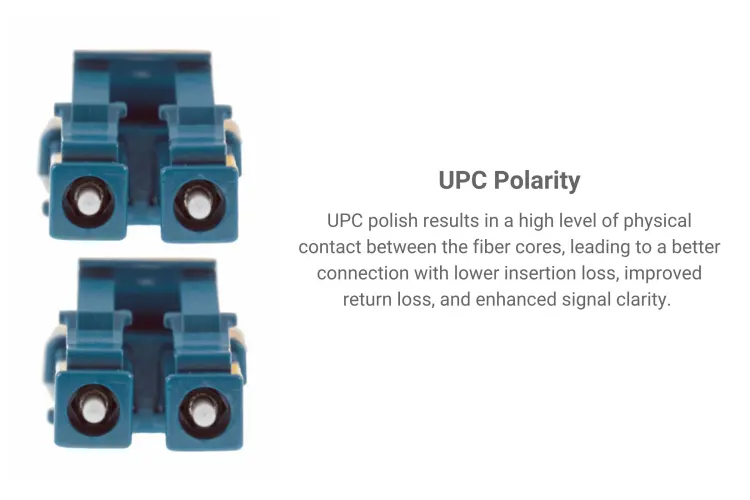

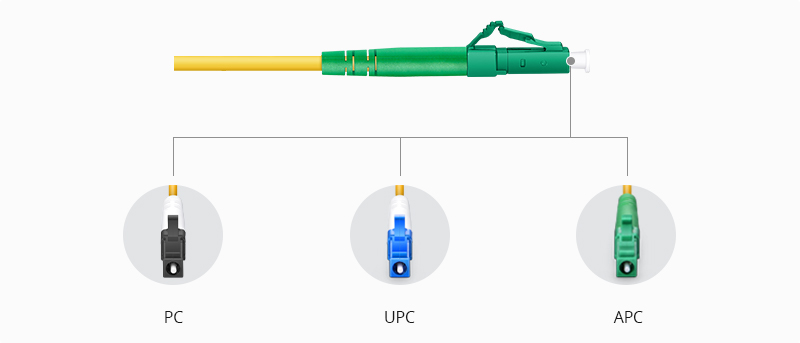

Step 3: Know the polish type

Remember the Polish type. Fiber optic connectors are available in PC, UPC, and APC polish. Therefore, we can divide them into three categories: PC, UPC, and APC connector; different polishes offer different performance and cost differences. Check with your supplier before ordering.

Identifying these three connector types is made convenient by the color code:

- Black is for the PC connector

- Green is for APC connector

- Blue is for UPC connector

- Beige is for multimode PC or UPC connector

- Aqua is for OM3 PC or UPC connector

Remember that different manufacturers may have varying color coding conventions for fiber connectors, so it’s important to always double-check before ordering.

FAQs

Q: What should I do if I install an SC connector but require an LC type?

A: In this case, you may use a fiber optic adapter like an SC-LC hybrid, which converts the SC to an LC connector.

Q: How do you connect fiber optic cable to the connector?

A: Take the LC fiber cable as an example. First, move the dust cover, then insert it into the LC connector carefully. Don’t touch the fiber end face to avoid any dirt.

Q: How do you connect two fiber optic cable connectors?

A: You need a suitable fiber optic adapter, such as connecting two LC fiber cables via an LC fiber adapter or an LC-SC fiber adapter to connect the LC and SC fiber cables.

Q: Why so many fiber optic connectors?

A: Indeed, many fiber connector types for different applications vary with the time change. However, modern fiber optic connectors generally include SC, LC, and MPO connectors. The others have fewer deployments.

APC vs UPC vs PC Fiber Connector, What is the Difference

What is Flat Fiber Connector

The flat fiber connector is like the figure above; the most apparent feature is the FLAT end face. When two flat fiber connections are joined, they naturally create a little air gap between the two ferrules, which is their main proble. This is partially due to the connectors’ relatively broad end faces, which enable numerous minor but noticeable defects to accumulate on the surface. With a core size of only 8 to 9 µm, this is not very useful for single-mode fiber cables, necessitating the development of Physical Contact (PC) connectors.

What is PC Fiber Connector?

PC is an abbreviation for “physical contact”. PC fiber connector refers to the connector with physical contact polished. It was first created in the 1980s to overcome the shortcomings of the original flat fiber connector.

Unlike flat fiber connectors, physical contact connectors have a slight taper around the endpoint. The cylindrical taper created by polishing the fiber ends reduces the air gap between the fiber ends that often occurs with flat connectors. Correspondingly, this small air gap reduces optical return loss (ORL), reducing the amount of light returning to the power supply and improving overall signal quality.

Generally, the typical return loss in single mode applications is about -40 dB, higher than the original flat polished style (-14 dB or about 4%). They are commonly used in multimode and single mode applications. However, as times have changed, this polishing style has become obsolete and is gradually replaced by the UPC polishing style.

What is UPC Fiber Connector?

UPC stands for Ultra Physical Contact. In fact, it is an enhanced version of the PC fiber connector. Based on the convex face properties of the PC, the connector utilizes an extended polishing method to create a better surface finish on the fiber.

Compared to standard PC connectors, this extended polishing results in lower optical return loss (ORL). Because of superior insertion and return loss performance, They have been used in many networks like digital TV, telephone, and data systems.

What is APC Fiber Connector?

APC stands for Angled Physical Contact. The emergence of APC fiber optic connectors is to achieve the need for lower back reflection. By grinding the radius of the end face of the fiber ferrule to an angle of 8°, we can minimize the back reflection. While that may not seem like much, the angled edges change the pitch at which light bounces back. So light reflected from the APC end face is directed into the cladding surrounding the fiber optic cable, rather than returning more directly to the fiber core.

The insertion loss of the APC fiber connector is comparable to that of the UPC fiber connector. Still, it can achieve a better optical return loss (-60dB or lower), which is better than other connectors.

But remember, unlike flat, PC, and UPC fiber connectors, this slight angle on the APC connector creates a rotation problem. Therefore, it can only be mated with other bevel-polished connectors, not with regular PC and UPC connectors paired, which would otherwise cause very high insertion loss.

APC connectors are commonly used in passive optical networks (PON) deployed in RF video or fiber-to-the-home (FTTP) networks because these systems are sensitive to any back reflections from connectors within the network.

APC vs. UPC vs. PC: What Are Their Differences?

Learning from the definition of APC, UPC, and PC fiber connectors, the most obvious difference is the fiber end face, return loss, and overall performance. Let’s look at the critical differences in the following chart.

Physical Appearance

- The first apparent difference is the ferrule end face. UPC and PC ferrule end face radius are polished at a 0° angle, while the APC end face radius is polished at an 8° angle.

- The second appearance difference is the connector color code. Generally, the APC connector was color coded as green, while the PC and UPC connectors were beige for multimode or blue single mode. These color codes also apply to fiber optic adapters, attenuators, and jumper assemblies. You may easily distinguish which type of polish style by the color of the fiber connector body.

Performance

Insert Loss (IL)

First, let’s look at the effect of insertion loss on the APC, UPC, and PC end face. Insertion loss refers to the optical power lost by measuring a paired connector. In the past, the insertion loss of angled physical contact connectors was usually high because of the significant losses caused by the air gap at the vertex offset.

However, due to improvements in connector design and manufacturing processes, the insertion loss of APC connectors has significantly been reduced, eventually rivaling the low insertion loss of UPC connectors.

Therefore, in today’s practice, we can ignore the insertion loss of these connectors.

Return Loss (RL)

Return loss is the amount of light the source reflects at an optical contact. It is the most significant difference between APC, UPC, and PC connectors.

Note: RL= -10xLog(PR/P) where PR = power reflected at the connector interface

From the introduction earlier in this article, we know that APC connectors use an end face that is polished at an 8° angle, resulting in the lowest return loss. According to industry standards, its return loss value will typically be -60 dB or better, while the UPC connector typically is -50 dB, and the PC connector typically is -40 dB.

Application

For specific applications that are more sensitive to return loss, APC connectors are preferred. Because these particular systems are susceptible to back reflection from any connector in the network, reflected light can adversely affect the signal. These areas include RF video signal transmission systems, FTTx applications, passive optical networks, and other WDM systems that use high wavelengths over single-mode fiber.

Then, for those applications that are not sensitive to return loss, UPC or PC connectors are preferred. PC connectors are generally used in telecom transmission applications, while UPC connectors are popular in digital TV, telephone, and data systems.

FAQ

Q: What type of connection are optical transceivers?

A: In most cases, it is UPC, like most SFP transceivers with UPC polished end faces. Remember, DON’T try to connect an APC fiber cable with the SFP transceiver.

Q: Is APC better than UPC?

A: Angled Physical Contact has better performance on return loss. However, only somewhere need better return loss. Therefore, it depends on your specific need and decides which is better.

Q: Can UPC connect to APC?

A: For the fiber connector, the answer is NOT. Because they are incompatible, This can damage the optical transmission.

But for the fiber adapter, ignore it because the only difference between them is the color, which means you may connect two APC connectors through the UPC adapter.

Q: Can UPC connect to the PC?

A: Yes, you can. Because those two fiber connectors are compatible.

Do SFP modules support APC, UPC, and PC fiber?

No, it does not. Since UPC and PC connectors are interchangeable, most SFP modules support both but can not support APC type.

If you use APC with SFP, it will risk physically harming the connectors and cause failer transmission. Rember to add a UPC to APC patch cable if you must use it.

Fiber Optic Connectors Explain 2

Fiber optic connectors might be small, but they play a big role in ensuring fast and reliable data transfers. They link fiber optic cables, allowing data to move quickly with minimal loss.

In this guide, you’ll explore various types of fiber optic cable connectors, each with unique features and best uses. Knowing what each connector does is essential, but it’s also important to match them with the right equipment, fiber type, and performance needs. We’ll also provide practical advice on installation, maintenance, and troubleshooting to help keep your system running smoothly.

What are Fiber Optic Connectors?

Optical fiber connectors are essential for networking. They link optical fibers and ensure data travels efficiently through light signals. If these connectors don’t work properly, your network’s reliability and performance can suffer.

So, why are these connectors so important? They help keep signal loss low and data transfer speeds high. With many different types of connectors, such as SC, LC, and ST, each is suitable for specific applications and environments. Choosing the right fiber optic connector ensures smooth and efficient network operations.

Types of Fiber Optic Connectors: Understanding the Differences

Choosing the right types of fiber optic connectors is important. It affects how well your network connects and performs. Here are the most common types of fiber optic cable connectors, types, applications and how to choose them.

1. SC Connector:

The SC connector, also known as the Subscriber Connector or Square Connector, is a common choice for data communication. It uses a push-pull locking mechanism that makes connections quick and secure. This connector features a 2.5 mm ferrule and a push-pull latching mechanism. This design makes connections both secure and easy to manage.

Known for its durability and straightforward use, the SC connector quickly gained popularity in network environments. Originally adopted for Gigabit Ethernet networks, it earned a reputation for reliable performance. These connectors are now commonly seen in telecom and data center settings.

Despite its advantages, the SC connector is gradually being replaced by smaller, more compact options. When you see visuals of SC connectors, they typically highlight their distinctive square shape and latch mechanism.

Advantages of SC Connectors

- Ease of Use: The push-pull design of the SC connector enables easy installation and removal without the need for specialized tools.

- Reliability: With its precise alignment mechanism, the SC connector offers stable and consistent performance over time.

- High Performance: These connectors are known for their low insertion loss and high return loss characteristics, making them ideal for demanding optical networking environments.

2. LC Connector

The LC connector has become a staple in data communication networks for its ability to save space and deliver high performance. It is often used in modern optical devices and high-density patch panels. The LC connector has a 1.25mm ferrule that aligns fibers accurately, ensuring low signal loss and high performance. Its design, including the small size and clip feature, makes it ideal for packed installations.

Common applications of the LC Connector include:

- Telecommunications networks

- Data centers

- Local area networks (LANs)

Advantages of the LC Connector:

- Compact size

- Low insertion loss

- High-performance capabilities

3. ST Connector

The ST (Straight Tip) connector, created by AT&T, is known for its bayonet mount and 2.5 mm ferrule. Its cylindrical shape holds the fiber securely and is designed for quick and easy connections. This durable connector works well for both short and long-distance applications, like campus networks and enterprise systems. Despite its reliability, the ST connector is now less common in new installations because newer types are preferred. Visuals often show its cylindrical shape and bayonet coupling mechanism.

Common Applications:

- Used in telecommunications networks

- Ideal for LANs (local area networks)

- Often found in medical imaging equipment

Advantages:

- Reliability: Ensures secure connections without signal loss.

- Durable: Can withstand repeated connections/disconnections.

- Easy Installation: Simple push-pull mechanism for quick setup.

4. MPO/MTP Connector

The Multi-Fiber Push-On and Multi-Fiber Termination Push-On (MPO and MTP) connectors revolutionize fiber optic connectivity by accommodating multiple fibers within a single connection. These connectors can support configurations of 12, 24, or even 36 fibers, making them indispensable in high-density applications where space is at a premium. Notably, the MTP connector is an enhanced version of the MPO, offering superior performance and accuracy.

Common Applications of MPO/MTP Connector:

- Data Centers: Essential for efficient, high-speed data transmission.

- Telecommunications Networks: Key for seamless long-distance communication.

- High-Density Environments: Ideal where space is at a premium.

- High-Throughput Scenarios: Facilitates quick and robust deployments.

Advantages of MPO/MTP Connector:

- High Fiber Count: Handles 12, 24, or 36 fibers.

- Enhanced Performance: MTP offers superior accuracy.

- Compact Design: Saves space in equipment racks.

- Efficient Installation: Connects multiple fibers quickly.

- Fast Setup: Push-on mechanism speeds up deployment.

- Reliable Connectivity: Ensures robust data transmission.

Understanding Pairs of Fiber Optic Connectors

When it comes to selecting the right fiber optic connectors, it’s essential to take a close look at the pairs highlighted below.

Fiber optic connectors difference between LC-LC, LC-SC, LC-ST, SC-SC and SC-ST

LC-LC Fiber Connector:

LC-LC connectors, known for their small size, work well in dense network setups. A cable with LC connectors on both ends delivers a compact, high-speed connection. This setup fits perfectly where space is tight and performance is key.

LC-SC Fiber Connector:

SC-LC fiber optic cable features an LC connector on one end and an SC connector on the other. The LC connector’s small size makes it suitable for high-density setups. The SC connector, with its push-pull locking system, provides a secure connection. This mix allows for flexible connections between different types of gear.

LC-ST Fiber Connector:

A ST-LC fiber optical cable combines an LC connector with an ST connector. The LC connector fits well in dense configurations. The ST connector, known for its round, bayonet-style coupling, is both reliable and easy to use. This makes the LC-ST setup a versatile choice for various environments.

SC-SC Fiber Connector:

SC-SC connectors are larger and use a push-pull design. A cable with SC connectors on both ends ensures stable and reliable connections. It’s ideal for network environments like data centers where strong connections are essential.

SC-ST Fiber Connector:

Featuring an SC connector on one end and an ST connector on the other, ST-SC fiber cable connector combines secure push-pull and bayonet-style connections. This setup offers flexibility and reliable performance across different network systems.

Polish of Fiber Optic Connectors: APC, UPC, UPC/APC

Image comparing APC (green, angled endface), UPC (grey, flat endface), and UPC/APC (combined endfaces) fiber optic connectors

- APC (Angled Physical Contact):APC fiber connectors have a polished surface at an 8-degree angle. This angled design minimizes back reflection or return loss by redirecting the reflected light out of the fiber core.

- UPC (Ultra Physical Contact)UPC connector fiber feature a flat polish on the end face, allowing for precise alignment between fibers to reduce insertion loss. While it offers improved performance compared to standard connectors, UPC does not address back reflection as effectively as APC.

- UPC/APC (Ultra Physical Contact/Angled Physical Contact):UPC/APC fiber connectors combine the benefits of both APC and UPC designs. The dual polish angles provide low insertion loss and minimal return loss for high-quality signal transmission in demanding applications where precision is key.

Modes of Fiber Optic Connectors: Single Mode vs Multimode

1. Single Mode:

- Uses single laser light for transmission

- Designed for longer distances

- Thinner core size (around 9 microns)

- Offers higher bandwidth but at a higher cost

- Ideal for telecommunication networks and long-haul applications

2. Multimode:

- Uses multiple LED light source for transmission

- Suited for shorter distances

- Larger core size (typically 50 or 62.5 microns)

- Lower bandwidth compared to single mode

- Commonly used in data centers, LANs, and short-distance connections

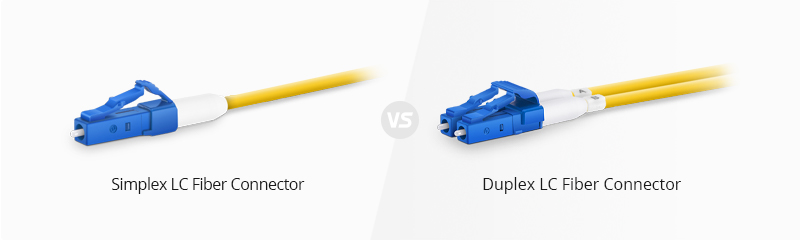

Transmissions of Fiber Optic Connectors: Simplex vs Duplex

Choosing the right fiber optic connector makes a big difference in data transmission. Simplex and duplex connectors each have their roles and suit different needs. Understanding these differences is essential for making the best choice.

- Simplex ConnectorsSimplex connectors transmit data in one direction only. They work well when you need to send data from one point to another without any need for feedback or return messages. This one-way communication is straightforward and reliable, making it ideal for simple setups where only one-way flow matters.

- Duplex ConnectorsUnlike simplex, duplex connectors support two-way data transmission. They allow information to move back and forth between two points simultaneously. The ability to send and receive data at the same time makes duplex connectors perfect for real-time or ongoing communication needs. If your setup requires simultaneous sending and receiving, duplex connectors are what you should choose.

Deciding between simplex and duplex connectors depends on your situation. For a simple one-way data transfer, simplex connectors are sufficient. However, if you need to handle two-way communication, duplex connectors are the better option.

Core and Cladding of Fiber Optic Connectors

To grasp fiber optic connectors, you need to know about their core and cladding sizes. Here’s a simple guide:

- 50/125 Connector50/125 optic fiber connector has a core that’s 50 microns wide and cladding at 125 microns. It’s great for short distances. You’ll typically find it in LANs where high-speed data transfer is crucial.

- 62.5/125 Connector62.5/125 fiber optic connector has a core of 62.5 microns and the same cladding diameter as the 50/125. It’s versatile. Whether you need it for short or long distances, it fits various network setups.

- 9/125 ConnectorThe core size here is just 9 microns. It’s built for long-distance use, making it ideal for covering large areas with little signal loss. Common in telecom and high-speed data situations.

By understanding these core and cladding sizes, you can pick the right fiber optic connector for your needs.

Optimizing Fiber Connectors: Best Practices for Installation and Maintenance

- Preparation is KeyBegin by meticulously cleaning both the connector and cable end faces using a lint-free wipe soaked in an alcohol solution. This initial step ensures optimal performance by eliminating any dirt or debris that could cause signal loss.

- Handle with CareAvoid excessive bending or twisting of the fiber cable when handling all types of fiber connectors. These delicate fibers require careful treatment to prevent damage. Utilize appropriate tools like cable grips and strain relief brackets to provide support during installation, safeguarding against potential mishaps.

- Regular Maintenance MattersRoutinely inspect your fiber connectors for any visible signs of wear or contamination. Promptly replace any damaged connectors to maintain peak performance and prevent signal degradation within your network.

Following these best practices, such as careful cleaning, careful handling, and regular inspections, will maintain a strong connection to your network infrastructure. Ongoing maintenance and attention to detail ensures that your fiber connectors remain reliable, extend their lifespan and guarantee uninterrupted performance for your business operations.

Final Thoughts

Before you decide on any fiber connector type, it’s crucial to ensure it fits seamlessly with your current network setup. Factors such as cable type, whether it is single mode or multimode, simplex or duplex, connector pairs should all be checked to avoid any compatibility issues down the road.

Still feeling uncertain about which optical fiber connector type suits your needs best? It’s wise to consult with our industry professionals today. Their expertise can offer valuable insights into the ideal choices based on your specific networking demands and requirements.

Fiber Optic Connectors Explain 3

Slide For fiber Connectors

SC/UPC to SC/UPC Fiber Optic Adapter 0dB Simplex Singlemode Connector