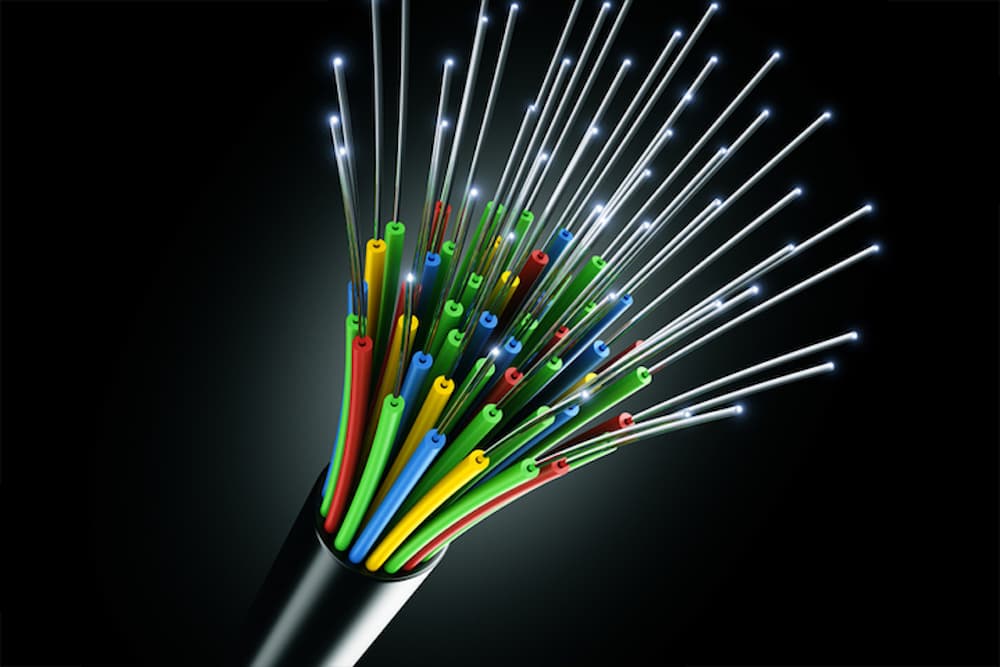

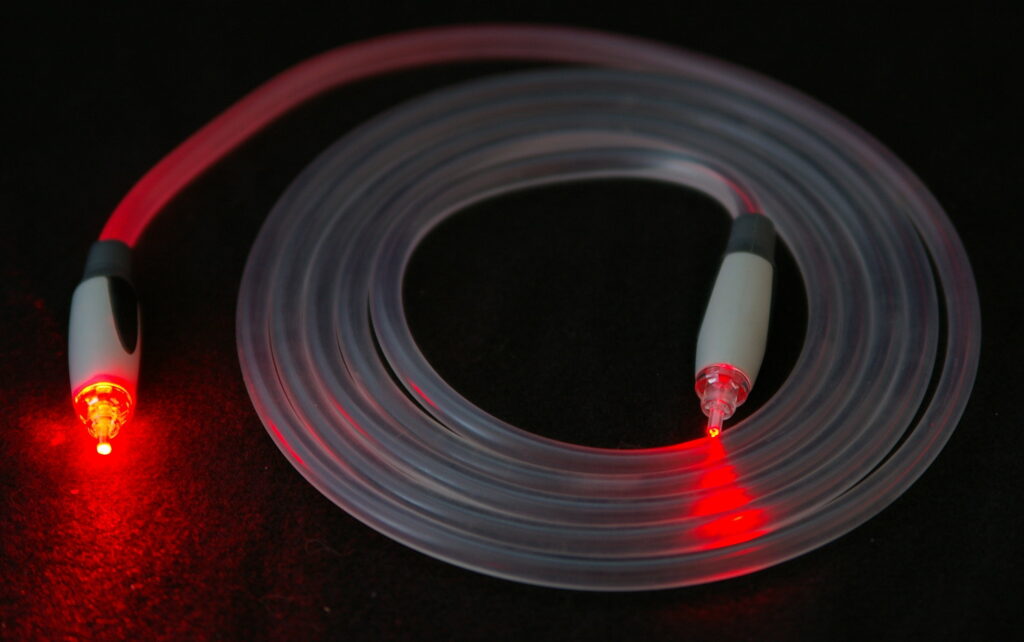

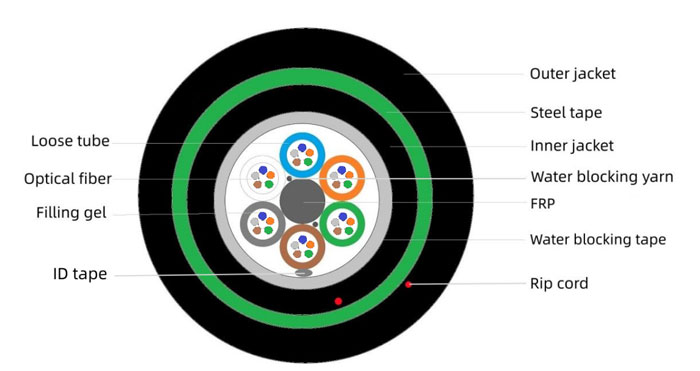

Fiber-optic cabling is widely used for high-speed Ethernet links over relatively long distances. It uses glass or plastic fiber as a medium through which light is “guided” to the other end of the link. The fiber-optic cable itself has several layers made from different materials and having different functions. The most important layer is the core, which is the very center of the cable. A light source, called transmitter or Tx, shines a light into the core. The core itself is surrounded by optical material called the cladding that keeps the light in the core using an optical technique called total internal reflection. Together the cladding and core create the environment to allow transmission of light over the cable.

What is Fiber Optics

Sir Charles Kao Kuen was a Chinese physicist and Nobel laureate who contributed to the development and use of fibre optics in telecommunications.

Fiber Optics or Optical Fiber is a technology that transmits data as a light pulse along a glass or plastic fiber. An Optical Fiber is a cylindrical fiber of glass that is hair-thin in size or any transparent dielectric medium. The fiber which is used for optical communication is waveguides made of transparent dielectrics. In this article, we will discuss Optical Fiber/Fiber Optics in detail.

What is Fiber Optics?

Fiber optics refers to the technology and method of transmitting data as light pulses along a glass or plastic strand or fiber. Fiber optic cables are used for long-distance and high-performance data networking. They are capable of transmitting data over longer distances and at higher bandwidths (data rates) than electrical cables, making them a critical component in modern telecommunications, internet, and computer networking.

Main Elements of Fiber Optics?

- Core: It is the central tube of very thin size made of optically transparent dielectric medium and carries the light transmitter to receiver and the core diameter may vary from about 5um to 100 um.

- Cladding: It is an outer optical material surrounding the core having a reflecting index lower than the core and cladding helps to keep the light within the core throughout the phenomena of total internal reflection.

- Buffer Coating: It is a plastic coating that protects the fiber made of silicon rubber. The typical diameter of the fiber after the coating is 250-300 um.

Types of fiber optic cables

Standard Fiber Wavelengths

- Multimode Fiber: 850nm and 1300nm

- Single Mode Fiber: 1310nm and 1550nm

Single-Mode Fiber (SMF)

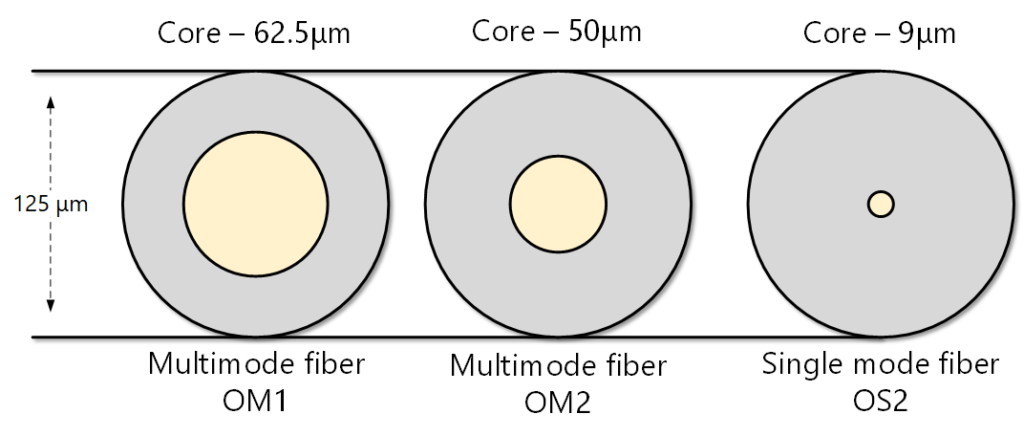

- Core Diameter: 8-10 microns

- Cladding Diameter: 125 microns (standard for all fiber cables)

- Light Transmission: Uses laser light sources (typically 1310 nm or 1550 nm wavelengths).

- Transmission Range: Designed for long-distance transmission (up to 40 – 80 km or more, depending on the equipment and wavelength).

- Bandwidth: Higher bandwidth than multi-mode fiber, supporting faster data rates over longer distances.

- Cost: Generally more expensive than multi-mode fiber due to precision manufacturing and components.

- Performance: Single-mode fiber experiences less signal loss and dispersion compared to multi-mode fiber, making it ideal for long-distance, high-speed networks.

Common Uses:

- Telecom networks

- Long-haul connections (inter-city, between data centers)

- Internet backbone networks

- High-speed Ethernet (10 GbE, 40 GbE, 100 GbE)

- Fiber to the home (FTTH) or fiber to the building (FTTB)

2. Multi-Mode Fiber (MMF)

- Core Diameter: Typically 50 or 62.5 microns (much larger than single-mode fiber).

- Cladding Diameter: 125 microns.

- Light Transmission: Uses LED light sources (usually 850 nm or 1310 nm wavelengths).

- Transmission Range: Optimized for shorter distances (up to 300metter 550metter 2 km for 10G Ethernet; less for higher-speed protocols like 40GbE or 100GbE).

- Bandwidth: Generally lower bandwidth than single-mode fiber, especially over long distances, due to signal dispersion (modal dispersion).

- Cost: Multi-mode fiber is less expensive than single-mode fiber, both for the cable itself and the equipment (such as transmitters and receivers).

Common Uses:

- Data centers (for intra-rack, inter-rack, and short-distance links)

- Local area networks (LANs)

- Enterprise networks

- High-speed Ethernet (1 GbE, 10 GbE, 40 GbE, 100 GbE) over shorter distances

- Building-to-building connections within a campus network

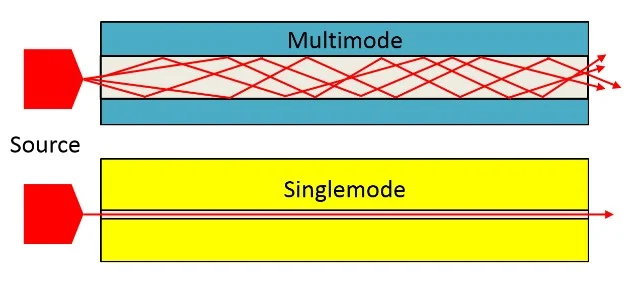

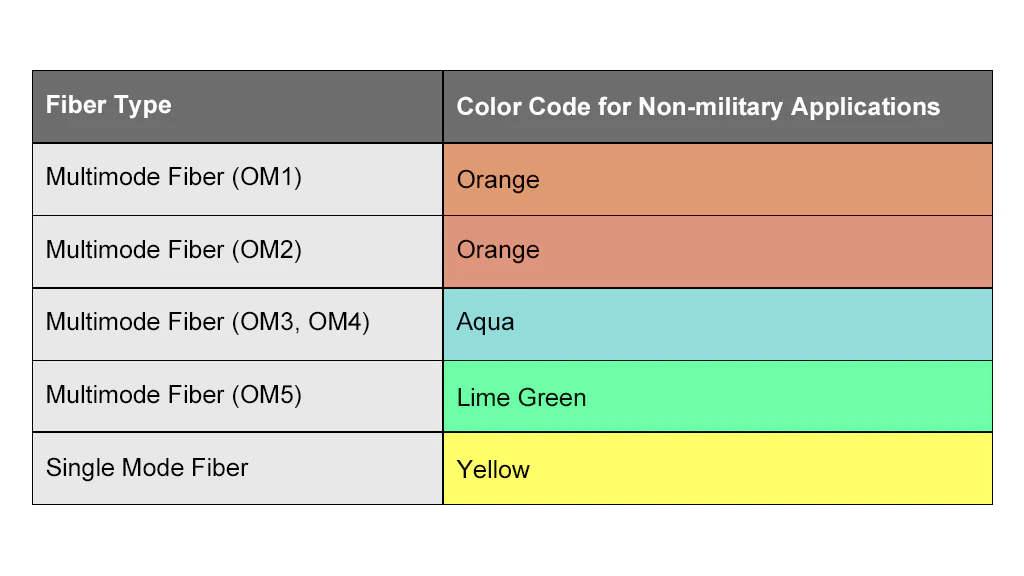

By Fiber Mode: Single Mode vs. Multimode

Single mode fiber and multimode fiber are the two primary categories of fiber optic cable. They differ in core size, transmission distance, and application scenarios:

Single mode fiber has a small core (around 8–10μm) that supports one light mode, enabling long-distance, high-bandwidth transmission. It’s commonly used in metro networks, long-haul communications, and backbone connections. Within SMF, OS1 and OS2 are the two major types—OS2 is optimized for outdoor long-distance cabling with lower attenuation, while OS1 has been largely phased out.

Multimode fiber has a larger core (50μm or 62.5μm) and supports multiple light paths. It’s ideal for short-distance communication in LANs, campus networks, and inside data centers

Multimode fiber has a larger core (50μm or 62.5μm) and supports multiple light paths. It’s ideal for short-distance communication in LANs, campus networks, and inside data centers

By Fiber Count: Simplex vs. Duplex

Fiber optic cables can be categorized by fiber count into simplex and duplex types:

Simplex: Contains a single fiber strand, typically used for unidirectional transmission or with BiDi (bidirectional) transceivers that send and receive signals over the same fiber.

Duplex: Consists of two fiber strands—one for transmit, one for receive—making it ideal for full-duplex communication and use with standard transceiver pairs.

Choose simplex cables for BiDi modules or one-way links. Opt for duplex in most two-way point-to-point applications.

By Cable Jacket: Riser (OFNR) vs. LSZH vs. Plenum (OFNP)

Fiber cable jacket types vary by fire safety rating and installation environment:

Choose the right jacket based on building fire codes and installation conditions to ensure both safety and compliance.

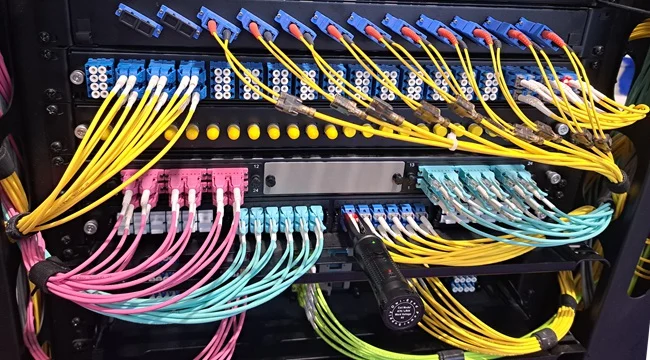

By Connector Type: LC, SC, ST, MTRJ & Others

Fiber optic patch cords come with various connector types, each designed to meet different performance and application needs. Some of the most common connector types include LC, SC, FC, ST, LSH, MU, and MTRJ. Each of these connectors has unique features, such as size, durability, and coupling mechanism, making them suitable for various networking environments. For a more detailed comparison of these connectors, refer to the article How Many Fiber Connector Types Do You Know? to understand the advantages and typical use cases of each type.

By Polishing Type: PC vs. UPC vs. APC

The polishing style of fiber connectors significantly affects return loss and overall signal performance:

For applications requiring minimal signal reflection and high precision, APC connectors are the preferred choice. For cost-effective, general-purpose deployments, UPC connectors provide reliable performance. For a complete comparison

Types of fiber optic cables Expalin 2

Explain Type -1

Types of Fibre

There are two primary types of fibre – multimode and singlemode.

Multimode fibre can carry multiple light rays (modes) at the same time by having varying optical properties at the core; essentially light travelling the shortest path (down the middle) travels the slowest.The larger core simplifies connections and takes advantage of the lower cost LED & VCSEL technologies which operate in the 850nm window. Due to dispersion the range is limited so it tends to be used as premises cabling when less than a kilometre. It comes in two core sizes, 62.5 and 50 microns.

Singlemode fibre has a much smaller core size of 9 microns and has a single light path and can travel much longer distances of up to 100km. These require more expensive electronics which operate in the 1310 and 1550nm windows and are typically used in longer distance LAN’s, Cable TV and telephony applications.

Explain Type – 2

Types of fiber optic cables

Multimode fiber and single-mode fiber are the two primary types of fiber optic cable.

Single-mode fiber

Single-mode fiber is used for longer distances due to the smaller diameter of the glass fiber core. This smaller diameter lessens the possibility for attenuation, which is a reduction in signal strength. The smaller opening isolates the light into a single beam, offering a more direct route and enabling the signal to travel a longer distance.

Single-mode fiber also has a considerably higher bandwidth than multimode fiber. The light source used for single-mode fiber is typically a laser. Single-mode fiber is usually more expensive as it requires precise calculations to produce the laser light in a smaller opening.

Multimode fiber

Multimode fiber is used for shorter distances because the larger core opening lets light signals bounce and reflect more along the way. The larger diameter permits multiple light pulses to be sent through the cable at one time, which results in more data transmission. This also means more possibility for signal loss, reduction or interference. Multimode fiber optics typically uses an LED to create the light pulse.

Fiber optics vs. copper cables

Copper wire cables were the traditional choice for telecommunication, networking and cable connections for years. Over time, however, fiber optics became a common alternative. Most telephone company long-distance lines are now made of fiber optic cables.

Optical fiber carries more information than conventional copper wire due to its higher bandwidth and faster speeds. Because glass does not conduct electricity, fiber optics is not subject to electromagnetic interference, which minimizes signal losses.

Advantages and disadvantages of fiber optics

Fiber optic cables are used mainly for their advantages over copper cables. Advantages include the following:

- They support higher bandwidth capacities.

- Light can travel further without needing as much of a signal boost.

- They are less susceptible to interference, such as electromagnetic interference.

- They can be submerged in water.

- Fiber optic cables are stronger, thinner and lighter than copper wire cables.

- They do not need to be maintained or replaced as frequently.

However, it is important to note that fiber optics do have disadvantages. These disadvantages include the following:

- Fiber optics is often more expensive than copper wire.

- Glass fiber requires more protection within an outer cable than copper.

- Installing new cabling is labor intensive.

- Fiber optic cables are often more fragile. For example, the fibers can be broken, or a signal can be lost if the cable is bent or curved around a radius of a few centimeters.

Fiber optics uses

Fiber optics uses

A range of industries use fiber optic cables for reliable and fast connectivity.

Computer networking and broadcasting

Computer networking is a common fiber optics use case due to optical fiber’s ability to transmit data and provide high bandwidth. Similarly, fiber optics is frequently used in broadcasting and electronics to provide better connections and performance.

Internet and cable television

Internet and cable television are two of the more common use cases for fiber optics. Fiber optics can be installed to support long-distance connections between computer networks in different locations.

Undersea environments

Fiber optic cables are used in more at-risk environments, like undersea cables, as they can be submerged in water and don’t need to be frequently replaced.

Military and space

Military and space industries also make use of optical fiber as a means of communication and signal transfer in addition to its ability to provide temperature sensing. Fiber optic cables can be beneficial due to their lighter weight and smaller size.

Medical

Fiber optics is frequently used in a variety of medical instruments to provide precise illumination. It also increasingly enables biomedical sensors that aid in minimally invasive medical procedures. Because optical fiber is not subject to electromagnetic interference, it is ideal for various tests like MRI scans. Other medical applications for fiber optics include X-ray imaging, endoscopy, light therapy and surgical microscopy.

Explain Type – 2

Who uses fiber optics?

Various industries now use fiber optics to transmit data, including health care, automotive, computer networking, and telecommunications. Let’s take a closer look at how each industry benefits from fiber optics.

Fiber optics in health care

Not only does fiber optics meet the health care industry’s high demand for networking, it has aided medical discoveries and the use of technology in this field. Devices like endoscopes, arthroscopes, bronchoscopes, X-rays, CAT scans, and MRIs all use fiber optics to provide doctors with better tools to diagnose patients and view specific body parts during surgery.

Fiber optics in the automotive industry

With innovations in safety, anti-collision sensors, and navigation systems, the automotive industry is taking advantage of fiber optics’ high bandwidth. Between autonomous driving, infotainment systems, and the now-required networking of a car’s electronic systems, cameras, radar, brakes, airbags, and so on, which uses POF to make all this possible.

Fiber optics in networking

Fiber optics in networking allows for increased speeds, creating high-speed internet. The ability of fiber optic cables to transport data over longer distances than coaxial cables makes them advantageous for internet service providers (ISPs). This enables the larger bandwidth and the ability to stream, play video games, and connect the Internet of Things (IoT) all on the same network with little slowdown.

Fiber optics in telecommunications

Like networking advantages, fiber optics in telecommunications allows for speed and a reliable signal to connect people across long distances. In addition, fiber optic cables have much less signal interference than copper coaxial cables. These advantages facilitated innovation and growth in the industry.

How to start a career in fiber optics

How to start a career in fiber optics

You can start a career in fiber optics by becoming FOA certified through certification training from a school approved by the Fiber Optic Association. Some employers offer on-the-job training, and you can also become certified after two years on the job.

Becoming FOA certified

The Certified Fiber Optic Technician (CFOT) is the beginner certification for fiber optic technicians; this requires demonstrating knowledge and skills in the field. To obtain the certification, you will have to pass an FOA examination. You can advance your career with an FOA specialist certification for those already certified. Certifications vary based on your skills but range from data center and residential cabling to fiber optic splicing and fiber optic network design.

Careers in fiber optics (with salaries)

The job outlook for telecommunication technicians projects 6 percent growth from 2022 to 2032, faster than the national average for all occupations . Below is a list of occupations in fiber optics:

- Fiber technician

- Tower technician

- Fiber optic splicer

- Telecommunications engineer

- Fiber optics design engineer

Look at each career, its requirements, and its average annual salary.

Fiber technician

Average annual salary 21k

Fiber technicians work to repair, install, and upgrade telecommunications systems. They may work to find weaknesses in a system, run testing, and determine the upgrades needed to ensure the system is functioning properly. You typically only need a high school diploma, GED, or sometimes an associate degree or certification for this role.

Tower technician

Average annual salary in India 13k To 15k Per Month

Tower technicians install, repair, and perform preventive maintenance on cell phone towers. They also work with coaxial cables, antennas, and fiber optics. You will climb cell phone towers to do your work, requiring training from a trade school for repair and safe tower climbing.

Fiber optic splicer

Average annual salary in india 21k To 28K Per Month

Fiber optic splicers use a fusion splicer to splice fiber optic cables together for concatenation and terminals. Becoming this type of technician requires a high school diploma or GED. You can also get a specialist certification called a CFOS/S from the FOA with a prerequisite of the CFOT certification.

Telecommunications engineer

Average annual salary in India 3 Lakh To 9 Lakh Per Year

Telecommunications engineers frequently specialize in a specific area, such as voice, data, or fiber, and work to lead the replacement, upgrade, and repair of telecommunications systems. This role often requires earning a bachelor’s degree in information technology with telecommunications experience.

Fiber optics design engineer

Average annual salary in India 4 Lakh Per Yaer

Fiber optics design engineers work with clients to analyze their current system, then make a plan and work with many different departments to install a fiber optics system. To qualify for this role, you must have knowledge of network topology, fiber splicing, routing, and leadership skills. Employers typically look for candidates with a bachelor’s degree in engineering or telecommunications.

How to start a career in fiber optics Explain 2

Starting a career in fiber optics is a great choice—there’s strong demand in telecom, data centers, ISPs, and smart infrastructure. Here’s a clear, beginner-friendly roadmap 👇

1. Understand the Field

Fiber optics careers usually fall into a few roles:

Fiber Optic Technician – installs, splices, tests fiber cables

OSP (Outside Plant) Technician – works on underground/aerial networks

ISP / Telecom Technician – customer installs & maintenance

Data Center Technician – fiber inside buildings & server rooms

Network / Fiber Engineer – design, planning, advanced troubleshooting

If you like hands-on work, start as a technician.

2. Learn the Basics (No Degree Required)

You don’t need a college degree to begin.

Learn:

What fiber optics is (single-mode vs multimode)

Cable types (loose tube, tight buffer)

Splicing (fusion vs mechanical)

Testing tools (OTDR, power meter, light source)

Safety basics (glass shards, lasers)

Free & Low-Cost Learning

YouTube: The Fiber Optic Technician, FOA, Telecom Infra Project

Online platforms: Coursera, Udemy (fiber optic basics courses)

Read: FOA (Fiber Optic Association) study guides

3. Get Certified (Very Important)

Certifications make you employable fast.

Entry-Level Certifications

ETA Fiber Optic Technician (FOT-ETA)

FOA CFOT (Certified Fiber Optic Technician) (Highly respected)

These can often be completed in 1–2 weeks.

4. Get Hands-On Practice

Employers care about skills more than grades.

Ways to practice:

Enroll in a short fiber optic bootcamp

Apprenticeships with telecom companies

Entry-level jobs:

Fiber helper

Cable technician

Telecom installer

If possible, practice:

Stripping fiber

Cleaving

Fusion splicing

Testing with a power meter

5. Apply for Entry-Level Jobs

Search for:

Fiber Optic Technician (Junior)

Network Cabling Technician

Telecom Technician

ISP Installer

Where:

Local ISPs

Telecom companies

Construction contractors

Data centers

Government infrastructure projects

6. Build Your Career Path

After 1–3 years, you can move into:

Senior Fiber Technician

Fiber Splicing Specialist

Network Engineer

Project Supervisor

Field Trainer

Own Fiber Contracting Business

7. Tools You’ll Eventually Need

You don’t need everything at first, but know them:

Fusion splicer

OTDR

Fiber cleaver

Power meter & light source

Fiber microscope

(Some employers provide tools.)

8. Salary Expectations (Approx.)

Entry-level: $40k–$55k/year

Mid-level: $60k–$80k

Specialized / Engineer: $90k+

9. Soft Skills That Matter

Attention to detail

Problem-solving

Willingness to work outdoors

Basic networking knowledge

Good documentation skills

10. Next Step (Action Plan)

If you’re starting from zero:

Learn basics online (1–2 weeks)

Get CFOT or FOT certification

Apply for fiber helper / technician roles

Gain hands-on experience

Specialize (splicing, testing, engineering)

Submarine Fiber Cable

Underground Fiber Optic Cable

Specialty Fiber Cable Types

These fiber optic cables are designed for harsh, high-density, or specialized environments:

Armored Cables

Armored fiber optic cables feature stainless steel or Kevlar reinforcement inside the jacket, protecting against crushing, bending, and rodents. Ideal for factory floors, data centers, or heavy-duty environments.

Industrial Cables

Industrial fiber optic cables are designed for harsh environments with vibration, oil, chemicals, and extreme temperatures. Featuring reinforced jackets and high-strength materials, they offer strong tensile, impact, and crush resistance. Commonly used in factory automation, energy systems, and outdoor networks, these cables support direct burial, underground conduits, and inter-building links, ensuring stable performance in rugged industrial settings.

High Density Cables

High-density fiber cables, especially those with LC uniboot designs, are engineered to reduce cable bulk and simplify cable management in space-constrained environments. The uniboot structure combines two fibers into a single jacket, reducing cable volume by up to 50% compared to standard duplex cables. This streamlined design improves airflow, reduces rack congestion, and enhances system organization, making it ideal for data centers and other high-density network deployments where space efficiency and routing clarity are critical.

FTTA Cables

FTTA (Fiber to the Antenna) cables are specialized for outdoor telecom infrastructure, especially in 4G LTE and 5G base station setups. Designed with weatherproofing and rugged sheathing, these cables resist UV, moisture, and extreme temperatures. They enable high-performance connections between RRUs (Remote Radio Units) and BBUs (Baseband Units) or AAUs (Active Antenna Units), delivering low signal loss and high reliability in tower environments.

Multifiber Cables

Multifiber cables are essentially multiple standard fiber patch cords bundled together, making installation faster and easier. These are available in both indoor and indoor/outdoor versions, catering to various deployment scenarios.

Outdoor Fiber Optic Cable

There are different types of outdoor fiber optic cables including underground fiber cables, direct burial fiber cables, aerial fiber cables, and submarine fiber cables. Outdoor fiber optic cables can be easily affected by external environments and they should be more robust than indoor fiber optic cables. We’ll give a brief introduction to outdoor fiber optic cable in this article.

1. Aerial Fiber Optic Cable · Messenger Wire

Aerial Fiber Optic Cables:Aerial fiber optic cables can often be seen hanging on the poles or buildings. They are usually exposed to extreme environments such as wind, ice, and storm, so it can be easier to damage than direct burial fiber cables and pipe fiber optic cables. Aerial fiber optic cables are often divided into two types: self-supporting and catenary wire.

GYTC8S Aerial Fiber Optic Cable, single mode G652D 12 24 48 96 144 core

GYFTC8S figure 8 cable, stranded loose tube optical fiber cables for outdoor use. Selected high quality optical fiber ensure the optical fiber cable have excellent transmission properties.The unique fiber excess length control method provides the cable with mechanical and environment properties.Very strict material and manufacturing guarantees the cable can stably work for more than 30 years. Total cross-section water-resistant structure makes cable have excellent properties of moisture resistance. Special jelly filled in the loose tube provides the fibers with critical protection Steel tape strength optical fiber cable in crush resistance. Figure-8 self-supporting structure, high tension strength, facilitate in aerial, low installation costs.

What Is Aerial Fiber Optic Cable?

Aerial fiber optic cable is a type of fiber optic cables that is usually used for outside installation on poles. Due to its installation environment, the design of aerial fiber optic cable must consider to protect it from the destruction of the nature and man-made damage or theft. Aerial cable’s laying method is not hard to implement as it can utilize the existing overhead pole line to install that saves more in construction costs and shortens the construction period. Aerial cables are mainly used for secondary trunk level and below and usually applied to flat terrain or low fluctuation area. They are easily affected by the natural disasters, such as typhoons, ice, floods etc. as well as the influence of an outside force and the mechanical strength weakening in themselves. Therefore, the failure rate of aerial fiber optic cables are higher than the pipeline or directly buried fiber optic cables.

Types of Aerial Fiber Optic Cables

According to the installation methods, aerial fiber optic cables can be generally classified as two types: catenary wire and self-supporting. Catenary Wire Aerial Cable is regular outdoor loose tube cables that can be helically lashed to a messenger or another cable (common in CATV). Self-Supporting Aerial Cable, or All-Dielectric Self-Supporting (ADSS) cable (the common style such as Figure-8 Aerial Cables), has cable bonded to an insulated steel or all-dielectric messenger for support. ADSS Cables are usually made of heavier jackets and stronger metal or aramid strength members. Nowadays, the self-supporting aerial fiber optic cables are more widely used by people.

As a familiar self-supporting aerial cables, figure-8 self-supporting aerial cables are designed for easy and economical one-step installation and widely used in long-haul and building network communication. According to the structures and materials of the cables, there are several kinds of figure-8 self-supporting aerial fiber cbales in the market, such as GYTC8S, GYXTC8Y, GYXTC8S etc. We can see the differences between GYTC8S, GYXTC8Y and GYXTC8S through the detailed information below.

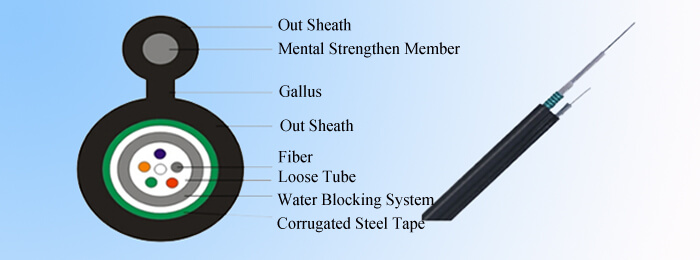

GYTC8S:GYTC8S is a typical self-supporting outdoor fiber optic cable. It’s suitable for aerial applications while its nice moisture resistance performance and crush resistance performance are suitable for duct and buried method. The metal strength member is made up of stranded wires as the supporting part that are completed with a polyethylene sheath to be figure 8 structure. Corrugated steel tape armored and polyethylene outer sheath provide the crush resistance and gun shot resistance features. As the central strength, the steel-wire strength member improves the tensile strength. In addition, it is surrounded by the loose tube and water blocking system.

Features:

Excellent mechanical and environmental performance. Small cable diameter, self-supporting, easily to install. Low dispersion and attenuation. Corrugated steel tape armored and polyethylene outer sheath providing crush resistance and gun shot resistance features. Cross section shows figure 8. Stranded wires as self-supporting member providing excellent strain performance and convenient installation. Steel-wire strength member provides good tensility, ensures tensile strength. Water blocking system to improve the waterproof ability.

GYXTC8Y:GYXTC8Y is a light self-supporting cable with the figure-8 shape in the cross section that is suitable for installation in aerial environment for long haul communications. High tensile strength of stranded wires meet the requirement of self-supporting. It can also be used for duct and buried method. The metal strength member is similar to the GYTC8S. Steel wires and loose tubes filled with waterproof compound to ensure compact and longitudinally water blocking.

Features:

Excellent mechanical and environmental performance. Small cable diameter, light cable weight, self-supporting, easily to install. Low dispersion and attenuation. Medium density polyethylene jacket: low friction installation, excellent protection from environmental hazards. Stainless steel or galvanized steel self-supporting. Load-supporting element is made of zinc-coated wire provides high resistance grade to long tension. High strength loose tube that is hydrolysis resistant. Light self-supporting cable with the figure-8 shape.

GYXTC8S:GYXTC8S is also suitable for installation in aerial environment for long-haul communications. This kind of figure-8 aerial cables is usually for 4-core to 12-core types. The water resistant tape provides water tight property. Corrugated steel tape and the polyethylene outer sheath provide crush resistance and gun shot resistance. The figure-8 steel wire works as self-supporting member providing excellent strain performance and convenient installation.

Features:

With small cable diameter, light cable weight, self-support. Excellent mechanical and environmental properties. Proper design and precise control for fiber excess length. Corrugated steel tape and the polyethylene outer sheath ensure crush resistance and gun shot resistance. The water resistant tape provides water tight property.

2. Direct Burial Fiber Cable

Direct Burial Fiber Cables: Direct burial fiber cables are buried underground, usually 0.8 to 1.2 meters deep. These cables should be resistant to dust, soil erosion, and animal chewing.

A direct burial fiber cable is an outdoor-rated cable designed to be installed directly underground, without needing extra protective conduits or ducts.

It is constructed with multiple layers that allow it to withstand moisture, soil pressure, temperature changes, and even rodent attacks — all while maintaining consistent optical performance for decades.

Key Construction Features

Direct burial fiber cables typically include the following protective components:

Thick Outer Jacket: Made of high-density polyethylene (HDPE) for resistance to moisture, abrasion, and chemicals.

Water-Blocking Materials: Gel or water-swellable tape keeps moisture from reaching the fibers.

Armored Layer (Optional): Corrugated steel tape or steel wire armor protects against crushing forces and rodent damage.

Strength Members: Kevlar yarns or FRP (fiber-reinforced plastic) rods provide tensile strength during installation.

Central Loose Tube Design: Fibers sit inside loose tubes, reducing stress and microbending losses.

Together, these features make direct burial fiber cables the preferred option for underground networks that require long-term durability with minimal maintenance.

Types and Advantages of Direct Burial Fiber Cables

Not all direct burial cables are the same. The best choice depends on your installation environment, network size, and protection requirements.

1. Types of Direct Burial Fiber Cables

| Cable Type | Description | Typical Use Case |

|---|---|---|

| Armored Direct Burial Cable | Features a corrugated steel tape or steel wire armor for maximum mechanical protection against soil pressure and rodents. | Ideal for harsh environments, rocky soil, or long-distance outdoor networks. |

| Non-Armored Direct Burial Cable | Uses a robust HDPE outer jacket and water-blocking gel, but without metal armor. Lighter and easier to install. | Suitable for soft soil or short-distance runs with low mechanical risk. |

| Loose Tube Gel-Filled Cable | Fibers are housed in gel-filled loose tubes to prevent moisture ingress and microbending. | Used in wet or flood-prone areas where water resistance is critical. |

| All-Dielectric Self-Supporting (ADSS) Cable | A non-metallic version designed for both underground and aerial routes, eliminating electrical conductivity risks. | Power substations, hybrid aerial-buried routes, or areas with electromagnetic interference. |

💬 Example: For long rural runs where burrowing animals are common, Baudcom’s armored loose-tube gel-filled fiber cable offers optimal protection and long service life.

Advantages of Direct Burial Fiber Cables

Direct burial fiber cables are designed for performance and protection. Here are the main benefits:

High Durability: Engineered to resist water, pressure, and environmental stress for decades.

Reduced Installation Cost: Eliminates the need for conduits in many areas, cutting materials and labor.

Low Maintenance: Once buried properly, the cable is protected from external damage and requires little upkeep.

Space Efficiency: No need for additional ducts or surface installations, making it ideal where space or access is limited.

Excellent Signal Stability: The buried environment shields the fiber from UV exposure and temperature swings.

Long Service Life: Properly installed direct burial cables can last 25–30 years with stable optical performance.

💡 Pro Tip: If you expect future network expansion, consider laying an extra empty conduit alongside the cable. It simplifies upgrades and eliminates future trenching costs.

Why Standard Fiber Cables Aren’t Suitable for Burial

After learning about the structure of direct burial cables, it’s natural to wonder — why not just use regular fiber cables underground?

Standard indoor or aerial fiber optic cables are designed for controlled environments like walls, ceilings, or poles. Underground conditions are much harsher, exposing cables to constant pressure, moisture, and soil movement. Using the wrong type of cable would quickly lead to failure and costly downtime.

Here’s why ordinary cables don’t work underground:

Moisture Exposure: Groundwater and rain can seep into the jacket, leading to signal loss and corrosion.

Crushing and Soil Pressure: The weight of compacted soil or rocks can deform and damage delicate fibers.

Rodent Activity: Burrowing animals may chew through unarmored cable jackets.

Temperature and Soil Movement: Expansion and contraction during seasonal changes can stress the fiber core.

💬 Example: Installing a standard indoor fiber under a lawn might work for a short time — until moisture seeps in or soil pressure cracks the jacket. In contrast, a Baudcom armored direct burial cable is specifically engineered to survive these underground hazards for years.

Direct Burial vs. Conduit Burial: Which is Better

You might be wondering, “If it’s so tough, why would anyone use a conduit?” It’s a valid question, and the answer lies in flexibility and future-proofing.

| Feature | Direct Burial Cable | Conduit Burial |

| Installation | Easier & Faster. A trench is dug, and the cable is laid directly in. | More Complex. A trench is dug, the conduit (pipe) is laid, and then the cable is pulled through it. |

| Cost | Generally Lower. Less material (no conduit) and less labor. | Higher. Cost of the conduit itself and the extra labor to install it. |

| Protection | Excellent. Built-in armor and water resistance. | Superior. The conduit provides an extra, physical barrier against all threats. |

| Future-Proofing | Poor. To upgrade the cable, you must dig again. | Excellent. Old cable can be easily pulled out and a new one pulled through without digging. |

| Best For | Long, straight runs under lawns, fields, and where future upgrades are unlikely. | Under driveways, roads, gardens, or anywhere you might want to upgrade the cable later without excavation. |

3. Pipe Fiber Optic Cables:

Pipe Fiber Optic Cables: Pipe fiber optic cables are usually installed in cities. The pipe usually features a good environment, so it has no special requirement for pipe fiber optic cables.

4. Underwater Fiber Optic Cables:

Underwater Fiber Optic Cables: Underwater fiber optic cables should withstand harsh environments, so they are generally made with a gel or powder. They should also feature excellent resistance to water and moisture. It has even higher requirements for submarine fiber optic cables and they should have at least 25 years of lifespan.

Tight Buffered vs Loose Tube

According to the construction of optic fiber cables, they can be divided into tight buffered and loose tube cables.

Tight buffered cables are usually made with 900μm buffered fibers. The fiber core is surrounded by aramid yarn or glass strength members in an outer jacket. The tight buffer inside the cable is used to protect the fiber from damage, especially during the installation. Tight buffered cables are often used in buildings or universities.

Loose tube fiber optic cables feature 250μm fibers in gel-filled loose tubes. Such kind of loose tube cables usually features a central member to offer stability. Loose tube fiber optic cables are more suitable for harsh outdoor environments as the gel-filled protective layer protects the cable from water and extreme weather.

What is Duct Fiber Optic Cable?

Duct fiber optic cable is specifically designed for installation in conduits or ducts. Duct fiber cable is commonly used in long-distance telecommunications networks and utility applications where the fiber optic cable needs to be protected from external factors. The number of fibers is 2 up to 288 fibers. Duct optical cables have a structure consisting of optical fibers enclosed within loose tubes, strength members, water-blocking materials, an optional armored layer, and an outer sheath. Each layer provides protection and functionality to ensure the reliability and longevity of the optical cable system.

According to the number of fiber cores, the structure of different types of duct fiber optic cable can be divided into a central loose tube and stranded loose tube fiber optic cable. Users can make corresponding requirements according to conditions of projects.

Duct Tube Fiber Optic Cable – GYTA

GYTA duct optic cable is a layer stranded structure. The optical fiber is placed in a loose tube, and the sleeve is filled with a waterproof compound. The center part is a metal reinforced member. For some fiber optic cable structure, a layer of polyethylene (PE) is required to be coasted outside the metal reinforced member. The loose tube (and the filling rope) is twisted around the central reinforcing member into a compact circular fiber optic cable and filled with a water blocking system. The plastic coated aluminum strip (APL) is longitudinally wrapped and extruded into a polyethylene sheath to form a fiber optic cable.

Fiber Cable Core

Fiber optic cables are available with varying core (or fiber) counts to accommodate different network needs, from small-scale installations to large, high-capacity network infrastructure. The number of cores (fibers) in a cable determines its capacity for transmitting data and the number of independent channels it can support. The core count typically ranges from a few fibers to hundreds of fibers.

Common Fiber Core Counts and Their Applications:

1. – Fiber Optic Cable Core Single

- Description: A cable with 1 fiber core.

- Use Case: Rarely used in network installations because single fibers are often used as part of multi-fiber cables.

- Applications: Point-to-point connections, custom installations, or test cables.

2. 2-Core Fiber Optic Cable

- Description: Contains 2 fiber cores.

- Use Case: Duplex cables, one core for transmit and the other for receive, used for bi-directional communication.

- Applications: Simplex communication or fiber to the home (FTTH), short-range LAN connections, and telecommunications.

3. 4-Core Fiber Optic Cable

- Description: Contains 4 fiber cores.

- Use Case: Often used for local area networks (LANs), fiber optic patch cords, and short-range communication.

- Applications: Used for fiber-to-the-building (FTTB) and small-scale network installations.

4. 6-Core Fiber Optic Cable

- Description: Contains 6 fiber cores.

- Use Case: Common for medium-density applications.

- Applications: Used in data centers for small interconnections and medium-length building-to-building fiber links.

5. 12-Core Fiber Optic Cable

- Description: Contains 12 fiber cores.

- Use Case: Used in medium-density networks or short to medium distance applications.

- Applications: Common in data centers, campus networks, and telecom backbones. Also used in fiber patch panels.

6. 24-Core Fiber Optic Cable

- Description: Contains 24 fiber cores.

- Use Case: For higher-density installations and larger networks.

- Applications: Typically used in data centers, fiber backbone networks, and large campus networks.

7. 48-Core Fiber Optic Cable

- Description: Contains 48 fiber cores.

- Use Case: Used for high-capacity installations, capable of supporting multiple data channels in dense environments.

- Applications: Common in telecom networks, large-scale data centers, and long-haul networking.

8. 72-Core Fiber Optic Cable

- Description: Contains 72 fiber cores.

- Use Case: Used for very high-capacity installations, often in high-performance data centers and backbone networks.

- Applications: Large-scale fiber optic infrastructures, where a significant number of individual connections are needed.

9. 96-Core Fiber Optic Cable

- Description: Contains 96 fiber cores.

- Use Case: Ideal for large-scale network applications requiring massive data throughput.

- Applications: Typically used in core networks, data center backbones, and telecom infrastructure.

10. 144-Core Fiber Optic Cable

- Description: Contains 144 fiber cores.

- Use Case: Used in high-density network environments that need to accommodate a huge number of connections in a compact form factor.

- Applications: Often seen in large data centers, central offices, and telecom operator infrastructure.

11. 288-Core Fiber Optic Cable

- Description: Contains 288 fiber cores.

- Use Case: Extremely high-density installations, often for core networking or fiber optic distribution systems.

- Applications: Major telecom backbones, large data centers, fiber optic cable trunks for wide-area networking (WANs).

12. Up to 864-Core Fiber Optic Cable

- Description: Contains 864 fiber cores.

- Use Case: Typically used for massive scale installations requiring huge amounts of data bandwidth.

- Applications: Found in long-haul telecom infrastructures, large-scale data center interconnects, and major metropolitan area networks (MANs).

Types of Fiber Optic Cables by Core Count:

Loose Tube Cable: Designed for outdoor and long-distance applications, typically used for high-core count cables like 48-core, 72-core, and 144-core.

Tight-Buffered Cable: Used for indoor environments, such as data centers, and often seen with 12-core, 24-core, and 48-core configurations.

Ribbon Fiber Cable: A type of high-density cable where fibers are arranged in flat ribbons, allowing for high core counts (e.g., 96-core, 144-core).

Conclusion:

The number of fiber cores you choose will depend on your specific network needs, the density of connections required, and the distance over which data will be transmitted. Smaller core-count cables (e.g., 2, 4, 12) are ideal for local area networks and short-distance communications, while high-core cables (e.g., 48, 96, 144) are needed for backbone networks, data centers, and telecom infrastructures.

For massive networks with high data transmission needs, cables with 288, 432, or 864 cores may be used in telecom backbones and large data center interconnects.